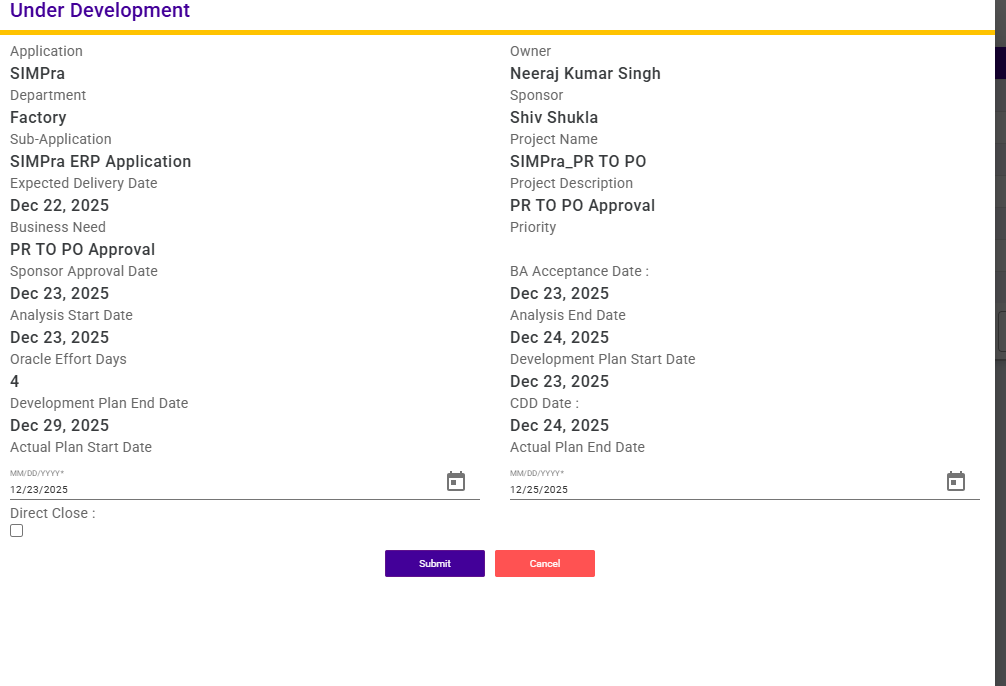

Right click on Batch List Context menu and select Production Entry

Production entry

Material Consumption Entry

- Total quantity received for production will appear under Received Qty.

- Enter the FG (Finished Good) quantity, Reject quantity, Fresh, and Sample for consumption.

- The system automatically calculates FG and Reject quantity based on the punching formula:

- FG = Total Quantity / 24

- Reject = Total Rejection Qty / 24

Example:

- Total Quantity = 100 → 100 / 24 = 4

→ System auto-fills FG = 4 under New Consumption

→ The same value is auto-updated in Printer Details → Finished Qty = 4

Total Reject Quantity = 50 → 50 / 24 = 2

→ System auto-fills Reject = 2

→ The same value auto-updates in Rejection Details → Rejected Qty = 2

Add Printer Details

- Under Printer Details, the system auto-calculates Finished Qty based on the FG value.

- Select Printer Name from the dropdown.

- Enter Quantity for that printer.

- Click Add Details to attach the printer entry.

- Multiple printers can be added depending on production distribution.

Click on SAVE request move to Production List